CPE (Chlorinated Polyethylene) plastic’s safety depends on its composition, processing, and application scenarios. Here’s a detailed breakdown:

1. Inherent Safety of Pure CPE

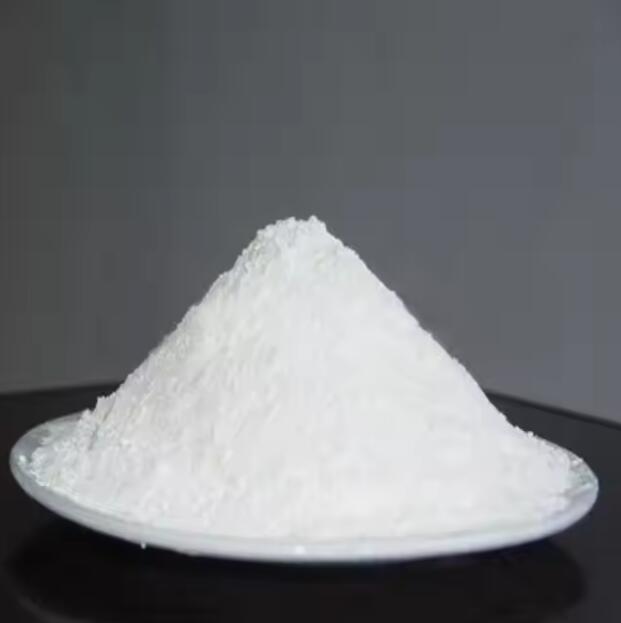

Pure CPE (e.g., the CPE 135A discussed earlier) is a non-toxic, odorless white powder with stable chemical properties. It does not contain heavy metals (like lead), phthalates, or other toxic additives in its raw form. Key safety traits include:

- No release of toxic substances (e.g., HCl) under normal use temperatures (unlike unmodified PVC, which requires heat stabilizers).

- High resistance to chemical corrosion (e.g., acids, alkalis) and aging, so it does not degrade easily to produce harmful byproducts during long-term use.

2. Safety in Practical Applications

CPE’s safety is further validated by its wide use in scenarios with strict safety requirements:

- PVC Modification for Daily/Medical Products: As an impact modifier, CPE 135A is added to PVC to improve toughness. When used in food-contact PVC (e.g., packaging films) or medical PVC (e.g., infusion tube materials), it is paired with eco-friendly stabilizers (e.g., Ca-Zn stabilizers, as mentioned in the previous processing aids section). In such cases, the final product meets global safety standards (e.g., FDA in the U.S., EU’s REACH Regulation) and does not pose health risks.

- Wire/Cable Sheaths & Building Materials: CPE is used in flame-retardant PVC wire sheaths and non-toxic building profiles (e.g., door/window frames). Its flame-retardant and low-smoke properties (it does not release toxic gases when burned) enhance safety in electrical and construction applications.

3. Potential Risks (and Mitigations)

Risks related to CPE are rare and mostly tied to improper processing or adulteration, not the material itself:

- High-Temperature Degradation (Avoidable): If CPE is processed at excessively high temperatures (>230°C) without proper control, it may partially decompose to release trace amounts of HCl. However, industrial processing (e.g., PVC extrusion, injection molding) strictly controls temperatures (160–220°C) to prevent this, and CPE’s thermal stability aligns with standard PVC processing parameters.

- Adulterated Low-Quality CPE: Some low-grade CPE products may contain impurities (e.g., residual solvents, heavy metal catalysts). To avoid this, choosing CPE from certified suppliers (meeting standards like GB/T 13646 in China or ASTM D in the U.S.) ensures safety.

4. Regulatory Recognition

CPE is recognized as a safe material by major global regulatory bodies:

- Approved for use in food-contact and medical-grade PVC products under regulations like the U.S. FDA 21 CFR §177.1520 and the EU’s Regulation (EC) No. 10/2011.

- Classified as a “low-risk polymer” in the EU’s REACH SVHC (Substances of Very High Concern) list, with no restrictions on its use in consumer or industrial products.

Conclusion

CPE plastic is safe for its intended applications when used as a pure, high-quality material and processed correctly. Its non-toxic nature, compliance with global safety standards, and widespread use in sensitive fields (food, medical, construction) confirm its safety. The key to ensuring safety lies in selecting certified CPE products and following standard industrial processing procedures.